- Author: Richard Smith

1st Announcement- Save the Date

2015 Salinas Valley Weed School

Thursday, November 12

8:00 a.m. to 12:00 noon

Agricultural Center Conference Room

(1432 Abbott Street, Salinas)

This meeting will cover a number of new techniques for controlling weeds in vegetable crops. In addition the effect of weeds on bagrada bug populations and new mechanical tools will be discussed.

4.0 Continuing education credits have been applied for. Please call ahead for special accommodations.

For more information call Richard Smith (831) 759-7357

See attached file for full agenda.

2015 Weed School Agenda

- Author: Richard Smith

Cilantro was produced on 5,543 acres in Monterey and Ventura Counties in 2011. The production of cilantro has shifted to high density 80-inch wide beds and a large proportion is now mechanically harvested. Hand weeding high density beds is very expensive and reduces the economic viability of this crop. As a result, there is a need for excellent weed control. Two broadleaf herbicides were registered on cilantro: Prefar and Caparol. Prefar was registered for a number of years and provides good control of a number of key weeds in cilantro such as purslane, lambsquarter and pigweed. Caparol was registered in 2012 and provides good weed control of a wider spectrum of weeds including the nightshades, shepherd’s purse, sow thistle, groundsel and others (see tables below).

Here is the situation with Prefar: EPA moved cilantro (also Mexican & Chinese parsley) out of the "Leafy vegetables" crop group 4 and placed it in the "Herbs and Spices" crop group 19. The issue is that crop group 19 Herbs and Spices has no tolerance for Prefar. Without a tolerance, Gowan Corp. can no longer support the 24c for cilantro. It places growers in a tricky situation, because they may have Prefar with the old label in reserve, but any detectable levels of Prefar residues are detected on cilantro, it could result in seizure of the crop. This is a regulatory snafu that may take some time to untangle; work is being done to resolve this situation but it is unclear how long it will take to resolve.

Caparol is also registered for use on cilantro, but there is a plant back restriction of 12 months prior to planting lettuce, broccoli, cauliflower and spinach. This is of course very difficult to work with this restriction in the Salinas and other coastal valleys.

Other weed control options: bed fumigation of cilantro prior to planting can be highly effective, but issues with the cost and working around buffer zones makes this option difficult to fit into a grower’s production budget as well as schedule. Cultural practices such as pregermination followed by shallow cultivation of emerged weeds prior to planting can help reduce weed pressure. Cilantro seed germinates slowly which opens the possibility of burning off a flush of weeds (with an herbicide or propane flamer) following planting but prior to the emergence of the cilantro. This is a tricky, but highly effective technique for reducing weed density.

In summary, we have a number of regulatory issues that need to be addressed in order use the broadleaf herbicides without difficulty. We will need to continue to work with the regulators and registrants to resolve these issues as quick as possible.

(Click on tables and images to Enlarge)

- Author: Richard Smith

The development of improved cultivation technology for row crop production has been an active area of research, and has made significant progress in recent years. Currently, standard cultivation removes weeds from the majority of the bed using sweeps, knives, coulters and blades. Typically a 4-inch wide band is left around the seedline. Weeds in the uncultivated band are typically removed by hand, and the density of weeds that occur there, determines how laborious and costly subsequent hand weeding will be.

There is technology to remove weeds from the seedline and it generally falls into two categories: 1) blind cultivation and 2) computer assisted cultivators. Implements used for blind cultivation are not guided by a person or machine. They are designed to be able to contact crop plants without significant damage, but yet remove young weed seedlings. Examples of this type of technology include 1) finger weeders, 2) torsion weeders and 3) various spring tine weeders (Photos 1-3). Finger and torsion weeders are useful in row crop scenarios and are designed for use on transplanted vegetables or large seeded vegetables such as beans and corn. Spring tine weeders are mostly used in field crops such as small grains. These devices are designed to take advantage of a size differential between the transplanted crop and newly emerged weeds. Cultivation is often done 1-2 weeks following transplanting. In our studies, these weeders supplement the action of standard cultivation and have the ability to reduce the time it takes to subsequently hand weed vegetables (Table 1).

Camera and computer assisted weeders are beginning to become available on the market. This technology can detect and distinguish crop plants in the seedline. An image of the seed row is captured by the camera and is then analyzed by the computer, which determines the location of crop plants in the seedline. Current technology uses the difference in size and color between the crop and the weeds, to distinguish the crop from weeds. These mechanical weed control machines were designed primarily for use on transplanted crops because the crop plants are initially larger than the weeds. Once the machine recognizes the crop plants it activates a weed removal implement. The implements that have been proposed or that are used by commercial units include swinging, spinning, or opening and closing blades, or other techniques such as flaming and the use of timed chemical sprays. The key for success is for the machine to take out as many weeds in the seedline as possible while not damaging crop plants. There has been more research and adoption of this technology in Europe; however, in California, there are two notable computer-assisted mechanical weed control machines either on the market or close to being commercialized for row crop production:

The Tillet Weeder, fabricated in England (Garford Corp, http://garford.com/) uses camera and computer technology to direct spinning round-blade with a notch cut out of one side. The blade travels in the seed line removing weeds, but when it encounters a crop plant, it spins around it by placing the plant in the notch (Photos 4 & 5). We evaluated this machine from 2009-2010 and found it to be effective in removing weeds from the seedline and reducing subsequent hand weeding time (http://cemonterey.ucdavis.edu/Vegetable_Crops/Weed_Reports/ for more info).

A machine is being developed by the University of Arizona and Mule Deer Automation (New Mexico) that sprays a chemical in a band application to remove unwanted plants. Various chemicals can be used in this machine such as acid or salt-based fertilizers (e.g., phosphoric acid or ammonium nitrate) or herbicides such as paraquat, pelargonic acid (Scythe®), or organic herbicides (Photo 6).

Other technologies that are being developed include alternative detection systems such as the use of lasers or x-rays to detect the stem of crops such as tomatoes. The development of plant maps by use of real time kinematic (RTK) global positioning systems (GPS) is being used in field crops. This technology allows for closer and more precise guidance of standard cultivators. This technology has not been applied to vegetable production to any extent in our area, but is being researched as a technique to someday guide in-seedline cultivators.

Technology will continue to develop and improve in the coming years. Computer-assisted mechanical weed control machines can provide an alternative option for weed control in vegetable crop production. These technologies do not entirely replace the need for hand labor, but they can make subsequent hand weeding operations less costly and more efficient.

Photos 1-3. Blind cultivation weeders: Finger weeders - left, torsion weeders - middle and spring tine weeder – right

Photos 4 & 5. The Tillet Weeder is a commercially available mechanical weed control machine that uses computer technology and a spinning blade to remove weeds. Left photo: The disc-shaped cultivation blades are lifted up so you can observe the notched cut-out that allows the blade to spin around crop plants. Right photo: Thinning lettuce.

Photo 6. Lettuce thinned and weeded with the University of Arizona/Mule Deer Automation prototype. The unwanted plants were treated with ammonium nitrate (AN20) fertilizer (in dark gray rectangular areas) and will die in a matter of days.

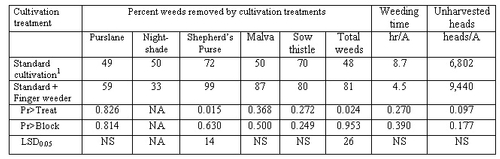

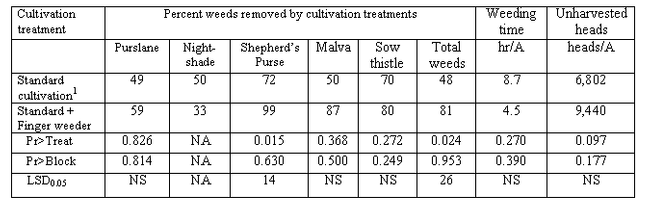

Table 1. 2010 finger weeder trial. Weed removal by cultivation treatments, weeding time and yield evaluation (count of heads remaining in field after harvest operation)

For further information on automated cultivators for vegetable crops:

Blind Cultivators

- YouTube video on blind cultivation techniques developed by UCCE, Monterey County: http://www.youtube.com/watch?v=I4kzebMG6rE

- Buddingh Weeder Co. (finger weeder and others) http://www.buddinghweeder.com/

- Einboch (spring tine weeder) http://www.einboeck.at/index.php?lang=en

- Frato Machine Import (torsion weeder) http://www.frato.nl/UK/torsiewieder-UK.htm

- Kovar (spring tine weeder) http://www.kovarsales.com/weederharrow.html

- Kress Company (finger weeder) http://www.kress-landtechnik.de/

- Red Dragon (flame weeder) http://www.flameengineering.com/Agricultural_Flamers.html

Computer Assisted Cultivators

- Garford Agricultural Equipment http://www.garford.com/index.html

- Frank Poulsen Engineering http://www.visionweeding.com/Products/Intra%20Row%20Weeding/ROBOVATOR.htm

- Ramsey Highlander http://www.ramsayhighlander.com/products/spinach-spring/spinach.htm

- Steketee Corporation (Netherlands): http://www.steketee.com/category/Mechanische-onkruidbestrijding (also see YouTube of their implement: http://www.youtube.com/watch?v=y7PJWwAAo1U

- University of Arizona (Mark Siemens) http://extension.arizona.edu/programs/specialty-crops-mechanization

- University of California, Davis (David Slaughter) http://bae.engineering.ucdavis.edu/pages/faculty/slaughter.html and http://baesil.engineering.ucdavis.edu/BAESIL/AutoWeedControl.html (videos of the implement)

- Author: Richard Smith

A video entitled, "Alternative Cultivators for Organic Vegetable Production" is now available on YouTube. The video was produced by Aaron Heinrich and Richard Smith and presents information on new developments in automated weed control technology and research information on blind cultivators such as torsion and finger weeders. The video can be accessed at:

http://www.youtube.com/watch?v=I4kzebMG6rE

For more information on alternative cultivation see the blog below. Also, go to

http://cemonterey.ucdavis.edu/Vegetable_Crops/Weed_Reports/

for research reports on precision cultivation.

- Author: Richard Smith

The development of improved cultivation technology for row crop production has been an active area of research, and has made significant progress in recent years. Currently, standard cultivation removes weeds from the majority of the bed using sweeps, knives, coulters and blades. Typically a 4-inch wide band is left around the seedline. Weeds in the uncultivated band are typically removed by hand, and the density of weeds that occur there, determines how laborious and costly subsequent hand weeding will be.

There is technology to remove weeds from the seedline and it generally falls into two categories: 1) blind cultivation and 2) computer assisted cultivators. Implements used for blind cultivation are not guided by a person or machine. They are designed to be able to contact crop plants without significant damage, but yet remove young weed seedlings. Examples of this type of technology include 1) finger weeders, 2) torsion weeders and 3) various spring tine weeders (Photos 1-3). Finger and torsion weeders are useful in row crop scenarios and are designed for use on transplanted vegetables or large seeded vegetables such as beans and corn. Spring tine weeders are mostly used in field crops such as small grains. These devices are designed to take advantage of a size differential between the transplanted crop and newly emerged weeds. Cultivation is often done 1-2 weeks following transplanting. In our studies, these weeders supplement the action of standard cultivation and have the ability to reduce the time it takes to subsequently hand weed vegetables (Table 1).

Camera and computer assisted weeders are beginning to become available on the market. This technology can detect and distinguish crop plants in the seedline. An image of the seed row is captured by the camera and is then analyzed by the computer, which determines the location of crop plants in the seedline. Current technology uses the difference in size and color between the crop and the weeds, to distinguish the crop from weeds. These mechanical weed control machines were designed primarily for use on transplanted crops because the crop plants are initially larger than the weeds. Once the machine recognizes the crop plants it activates a weed removal implement. The implements that have been proposed or that are used by commercial units include swinging, spinning, or opening and closing blades, or other techniques such as flaming and the use of timed chemical sprays. The key for success is for the machine to take out as many weeds in the seedline as possible while not damaging crop plants. There has been more research and adoption of this technology in Europe; however, in California, there are two notable computer-assisted mechanical weed control machines either on the market or close to being commercialized for row crop production:

The Tillet Weeder, fabricated in England (Garford Corp, http://garford.com/) uses camera and computer technology to direct spinning round-blade with a notch cut out of one side. The blade travels in the seed line removing weeds, but when it encounters a crop plant, it spins around it by placing the plant in the notch (Photos 4 & 5). We evaluated this machine from 2009-2010 and found it to be effective in removing weeds from the seedline and reducing subsequent hand weeding time (http://cemonterey.ucdavis.edu/Vegetable_Crops/Weed_Reports/ for more info).

A machine is being developed by the University of Arizona and Mule Deer Automation (New Mexico) that sprays a chemical in a band application to remove unwanted plants. Various chemicals can be used in this machine such as acid or salt-based fertilizers (e.g., phosphoric acid or ammonium nitrate) or herbicides such as paraquat, pelargonic acid (Scythe®), or organic herbicides (Photo 6).

Other technologies that are being developed include alternative detection systems such as the use of lasers or x-rays to detect the stem of crops such as tomatoes. The development of plant maps by use of real time kinematic (RTK) global positioning systems (GPS) is being used in field crops. This technology allows for closer and more precise guidance of standard cultivators. This technology has not been applied to vegetable production to any extent in our area, but is being researched as a technique to someday guide in-seedline cultivators.

Technology will continue to develop and improve in the coming years. Computer-assisted mechanical weed control machines can provide an alternative option for weed control in vegetable crop production. These technologies do not entirely replace the need for hand labor, but they can make subsequent hand weeding operations less costly and more efficient.

Photo 6. Lettuce thinned and weeded with the University of Arizona/Mule Deer Automation prototype. The unwanted plants were treated with ammonium nitrate (AN20) fertilizer (in dark gray rectangular areas) and will die in a matter of days.

For further information on automated cultivators for vegetable crops:

Blind Cultivators

- YouTube video on blind cultivation techniques developed by UCCE, Monterey County: http://www.youtube.com/watch?v=I4kzebMG6rE

- Buddingh Weeder Co. (finger weeder and others) http://www.buddinghweeder.com/

- Einboch (spring tine weeder) http://www.einboeck.at/index.php?lang=en

- Frato Machine Import (torsion weeder) http://www.frato.nl/UK/torsiewieder-UK.htm

- Kovar (spring tine weeder) http://www.kovarsales.com/weederharrow.html

- Kress Company (finger weeder) http://www.kress-landtechnik.de/

- Red Dragon (flame weeder) http://www.flameengineering.com/Agricultural_Flamers.html

Computer Assisted Cultivators

- Garford Agricultural Equipment http://www.garford.com/index.html

- Frank Poulsen Engineering http://www.visionweeding.com/Products/Intra%20Row%20Weeding/ROBOVATOR.htm

- Ramsey Highlander http://www.ramsayhighlander.com/products/spinach-spring/spinach.htm

- University of Arizona (Mark Siemens) http://extension.arizona.edu/programs/specialty-crops-mechanization

- University of California, Davis (David Slaughter) http://bae.engineering.ucdavis.edu/pages/faculty/slaughter.html and

http://baesil.engineering.ucdavis.edu/BAESIL/AutoWeedControl.html (videos of the implement)

Table 1. 2010 finger weeder trial. Weed removal by cultivation treatments, weeding time and yield evaluation (count of heads remaining in field after harvest operation)

1 – Standard cultivation leaves a 4 inch wide uncultivated band around the seedline