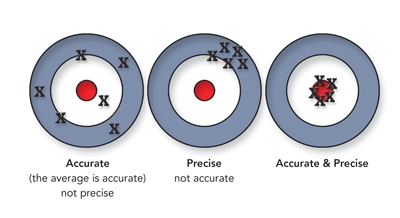

If you’ve ever taken target practice, you probably know that accuracy and precision are not necessarily the same things – a rifle that always shoots low and to the left of the bull’s-eye is precise but is not accurate. The same idea holds true for herbicide applications.

The most common causes of poor herbicide performance usually come down to 1) wrong herbicide(s) for the weed spectrum in the field, 2) wrong application timing with respect to growth stage or climactic conditions, and 3) poor application techniques. Proper field scouting and sound pest control advising are the first steps in taking care of the first two issues. Accuracy and precision are most directly affected by the spray rig and the operator.

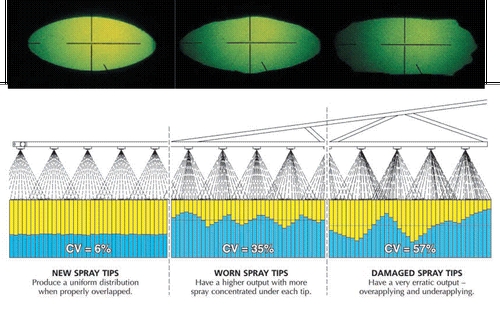

Herbicide application equipment should be calibrated on a regular basis; ideally once per year or more depending on the number of acres treated. First, all the nozzles on the spray boom should be checked to make sure that they are putting out the same volume in a given time period – any high or low output nozzles can result in poor weed control, wasted herbicide, or crop injury. Second, all nozzles should be checked to make sure they have a uniform spray pattern because any streams or dead spots in the pattern will also contribute to areas of under- or over-application.

Next, the sprayer pressure and ground speed of the rig should be verified to ensure that the correct application volume (gal/A) is used when calculating how much herbicide to add to the spray tank. Remember that increasing the spray pressure can contribute to smaller spray droplet size and increase chances for off-target drift. If higher spray volumes are needed, it may be better to adjust ground speed or nozzle size instead of increasing pressure above recommendations. Nozzle arrangement and boom height should also be considered to make sure that each nozzle is applying herbicide to the correct amount of area – nozzles too far apart or low boom height can result in skips between nozzles whereas too high can decrease the effective herbicide rate by treating a larger area than intended.

Once the spray rig is optimized for accurate and precise application, it’s time to address operator training. Only the sprayer operator or field supervisor can know the conditions in a field at the exact time the application occurs and it is up to them to recognize when conditions may not be right for accurate and precise applications. For example, high winds or gusty breezes could result in drift into the crop canopy or onto neighboring crops or areas of poor weed control. Conversely, some times of the year may be "too still" and an inversion layer may contribute to inaccurate applications, especially of the smallest spray droplets. The operator should routinely monitor spray patterns during the application to make sure that nozzles have not become plugged or out of alignment. If the spray rig ground speed is too fast for soil conditions (ie rough ground), it may be necessary for the operator to reduce speed to minimize bouncing of the nozzles which can lead to poor coverage and excessive drift but this will require an adjustment in the sprayer calibration process.

A few last points to consider when planning your fall and winter herbicide applications. Read and follow the directions on the herbicide label – the directions in this legal document are intended to provide weed control efficacy, crop safety, worker and bystander safety, and minimize effects on the environment. Pay attention to weed growth stage and stress condition – weed that are too large or under drought stress will be much more difficult to control that small, actively growing weeds. Think about pre-harvest intervals because applications too close to harvest could potentially result in illegal pesticide residues which may make the commodity non-saleable.

Finally, a take a little time at the beginning of the season to make sure that your equipment is set up and the operators are properly trained to make accurate and precise herbicide applications. The end result will be better weed control, reduced crop injury, and less wasted herbicides; all of which result in more bang for your weed control dollar!