Calag Archive

Calag Archive

Farmers describe irrigation costs, benefits: Labor costs may offset water savings of sprinkler systems

Publication Information

California Agriculture 50(1):11-18. https://doi.org/10.3733/ca.v050n01p11

Published January 01, 1996

Abstract

In recent years San Joaquin Valley farmers have improved irrigation methods to reduce subsurface drain water and make more efficient use of limited water supplies. Water-saving methods include sprinklers and gated pipe. However, these methods involve higher labor and energy costs, which may exceed the value of water saved when switching from surface irrigation methods, such as furrow irrigation with siphon tubes. Although more expensive, when sprinklers are used correctly they provide better leaching of salts while generating less subsurface drain water than surface methods. Public policies that reduce the capital cost of investing in sprinkler systems, and research to develop better surface irrigation methods, will assist farmers in continuing their efforts to improve irrigation water management while maintaining economic viability.

Full text

Furrow irrigation, using siphon tubes and earthen head ditches and tailwater ditches, is the most common method of irrigating field crops in the San Joaquin Valley. Its operation requires only one irrigator.

State and federal agencies significantly reduced water deliveries to the San Joaquin Valley from 1990 through 1992 due to persistent statewide drought. In 1993, environmental regulations further reduced surface water supplies, restricting the volume of water that could be pumped into supply canals from the Sacramento Delta (the delta formed by the Sacramento and San Joaquin Rivers). It is likely that these environmental regulations, and the increasing demand for water among all users in California, will continue to cause reductions in the volume of surface water delivered annually through the Delta to federal and state water agencies.

Many San Joaquin Valley farmers have improved their irrigation practices in recent years to maximize the benefit of water, which is higher priced and in shorter supply. Higher prices for irrigation water and the desire to reduce subsurface drainage water have also motivated farmers to manage surface irrigation more intensively and to use sprinkler systems for some irrigation events. The improved management of surface irrigations and the use of sprinklers allowed farmers to plant more acres of field crops during the drought than they could have irrigated using traditional methods.

Sprinklers irrigating a cotton field on the west side of the San Joaquin Valley. It is possible to improve water distribution by using sprinklers, which also leach salts more uniformly through the soil profile.

Tomatoes irrigated using gated pipe with erosion socks. Gated pipe irrigation systems have a higher capital cost, but reduce the seepage losses that occur in earthen head ditches.

However, most of the farm-level improvements have been more costly to implement than traditional irrigation methods. Often, the increased costs of capital, labor and energy exceed the savings that result from a reduction in the water volume purchased for irrigation. This is particularly true when comparing well-managed surface irrigation methods such as siphon tubes to sprinkler systems. Farmers who use sprinkler systems often derive additional benefits that are not easily quantified, such as improvements in distribution uniformity or the enhanced leaching of salts through the soil profile. However, the cost of purchasing and operating sprinkler systems significantly increases the average annual cost of irrigating.

Farmer interviews

We collected detailed information about irrigation practices and costs by interviewing 10 farmers in the 9,000-acre Broadview Water District, located in northwestern Fresno County, during August 1992 and May 1993. The farmers were interviewed individually by three researchers and the manager of the water district. The interviews, which lasted between 1 and 2 hours, were recorded on audiotape to preserve details about water management practices and costs. The tapes assisted researchers in constructing consistent descriptions of irrigation practices. Preliminary cost information developed from the interviews was presented to the farmers and the district manager for verification.

We selected Broadview Water District for this research because its farmers have made significant improvements in water management practices in recent years and their experience is helpful in describing both the benefits and costs of implementing those improvements. The farmers described their current water management practices and the labor requirements for four irrigation methods (siphon tubes, gated pipe, gated pipe in combination with earthen head ditches, and sprinklers) and four field crops (cotton, processing tomatoes, cantaloupes and alfalfa seed). Additional cost data were obtained from actual invoices for the purchase of sprinkler and gated pipe systems by Broadview farmers during 1992 and 1993.

Typical costs to purchase and maintain irrigation systems have been estimated using the Broadview information. Capital costs have been amortized over the expected useful life of each system, using a real interest rate of 4%. Wage rates, water prices, and energy costs are those reported in the farmer interviews. The specific irrigation methods, the number of irrigation events, and the labor requirements for each crop and technology combination have been developed using the information obtained during farmer interviews and the irrigation data compiled for all farmers in the district from 1990 through 1993.

Surface irrigation

The most common method of irrigating field crops in the San Joaquin Valley is furrow irrigation, using siphon tubes and earthen head ditches and tailwater ditches. Water flows by gravity through furrows that are typically either 1/4-mile or 1/6-mile long in 150-acre fields. In previous years, 1/2-mile furrows were very common in the valley, but these have been replaced by 1/4-mile and 1/6-mile furrows on most crops. Most cotton fields are now irrigated using 1/4-mile furrows; many tomato and melon fields are irrigated using 1/6-mile furrows. The shorter furrows allow farmers to achieve greater distribution uniformity, while reducing deep percolation and surface runoff. However, 1/4-mile furrows require one additional head ditch and tailwater ditch, and 1/6-mile furrows require two additional sets of ditches.

Gated pipe irrigation systems reduce the seepage losses that occur in earthen head ditches. Water is delivered to furrows through sliding gates in aluminum pipes that transport water from a turnout or canal. Gated pipe systems can be designed to deliver water in 1/2-mile, 1/4-mile or 1/6-mile furrows, by placing additional lines of gated pipe in each field. Some farmers prefer gated pipe systems when using shorter furrows, because there is no loss of crop area caused by the second and third sets of ditches that are required when using a siphon tube system. However, additional labor is required to place the gated pipes in each field before irrigations begin and to remove the pipe following the final irrigation event. In addition, farmers who receive their water in canals or open ditches must use a booster pump to lift water from the canal or ditch and place it in the gated pipe system. The capital cost of a gated pipe system increases significantly when furrow lengths are reduced from 1/2 mile to 1/4 mile or 1/4 mile because of the pipe that is required for each additional line.

Some farmers in the San Joaquin Valley have begun using a combination of gated pipe and siphon tubes in the same field, to reduce the capital cost of a gated pipe system while still achieving many of the benefits. These farmers use an earthen head ditch and siphon tubes at the high end of a field and use gated pipe to deliver water to the lower portion of the field. One line of gated pipe is used if the field is divided into 1/4-mile furrows and two lines are used if the field is divided into 1/6-mile furrows. This reduces the amount of gated pipe required to irrigate a 150-acre field by 2,640 feet, which represents a saving of about $10,000 at current pipe prices.

Labor requirements are similar when irrigating with siphon tubes or gated pipe. Both systems require supervision by one irrigator during both day and night to minimize surface runoff. The irrigator also moves the siphon tubes or opens and closes the gates, as necessary, when changing the irrigation set from one portion of a field to another. In addition, some farmers report that the labor requirement for opening and closing earthen ditches is similar to the labor requirement for placing gated pipe in the field and then removing it later in the year.

Many farmers who use surface irrigation methods laser level their fields every 10 or 12 years to improve distribution uniformity. Typical costs of laser leveling range from $60 per acre to $350 per acre in the San Joaquin Valley. The cost depends on the volume of soil that is cut and filled throughout a field during the leveling procedure. Fields that have been leveled in recent years require less work than fields that are being leveled for the first time. Because many of the fields in the region have been leveled in recent years, a laser-leveling cost of $60 per acre is used in this analysis.

Sprinkler irrigation systems

Many farmers have begun using sprinkler systems to irrigate field crops in response to rising water prices and reductions in water supply. It is possible to improve distribution uniformity by using sprinklers if the systems are operating correctly and if wind conditions are favorable. Sprinklers are also preferred by some farmers for pre-irrigations because they leach salts more uniformly through the soil profile. The initial cost of pipe and components for a sprinkler system is significantly higher than the initial cost for a siphon tube or gated pipe system. However, farmers using sprinklers for all irrigation events may be able to avoid the cost of laser lèveling because field characteristics are not the primary determinant of distribution uniformity when using sprinkler systems. Sprinkler system design, component wear and operating conditions have a greater influence on distribution uniformity than do field conditions.

TABLE 2. Typical row spacings and the days per irrigation event, using siphon tubes or gated pipe irrigation systems

Sprinkler systems require a pressurized water delivery in order to move water through the pipelines, risers and nozzles. Farmers who receive water delivery from a water district canal must install booster pumps to lift water from the canal and to pressurize their sprinkler systems. The initial cost of a booster pump and diesel engine is about $18,000, and the variable cost of pumping water is about $10 per acre-foot at current energy prices.

Sprinkler systems require significantly more labor than surface irrigation methods because the sprinkler lines must be moved at regular intervals to irrigate large fields. In the San Joaquin Valley, it is common to operate a sprinkler system for 12 hours or 24 hours, then move the sprinkler lines to the next portion of the field. A typical sprinkler system that includes six lateral lines must be moved 11 or 12 times when irrigating a 150-acre field because each lateral line delivers water to a 37-foot-wide portion of the field. Line movers are often hired for that task only, and they move lines in the early morning and early evening. Typically a separate person is hired to supervise the operation of the sprinklers and the booster pump during the day, and another person is hired to monitor the booster pump during the night.

Combining systems

Many farmers have begun using sprinklers for pre-irrigations and early irrigations of cotton and tomatoes, while using surface methods for late-season irrigations. These farmers achieve better leaching of salts during pre-irrigations and are able to use less water during early irrigations, when plants are small and root systems are not extensive. Some farmers use sprinklers to irrigate cotton throughout the season, but many prefer surface methods during July and August. Farmers must switch to surface methods on tomatoes to prevent damage that can be caused by placing water directly on the plants and fruit.

Cost-effective combinations of irrigation systems are achieved when irrigation strategies permit one set of sprinklers or gated pipe to be used on more than one crop in the same year. For example, the same sprinkler system that is used to pre-irrigate cotton fields from November through February can be used to irrigate young tomato plants in April and May. The same system can also be used for the first and second cotton irrigations in June and July. Many farmers have developed irrigation strategies that minimize the average cost of using sprinkler systems in combination with surface methods.

Capital costs

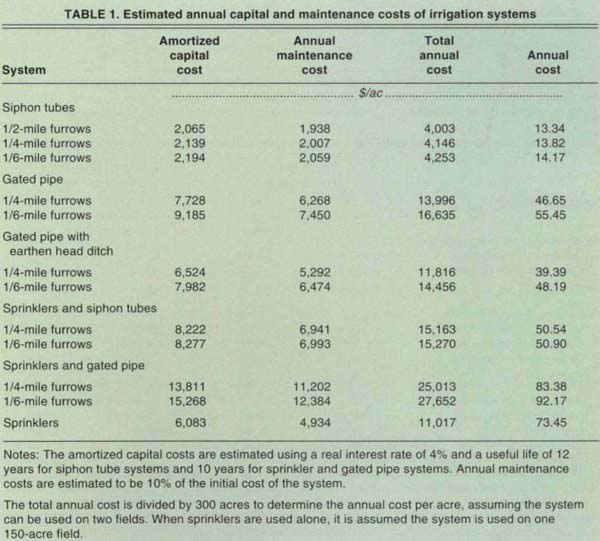

The estimated annual capital costs of siphon tube irrigation systems range from $13.34 per acre, for a traditional system with 1/2-mile furrows, to $13.82 per acre, for 1/4-mile furrows, and $14.17 per acre, for 1/6-mile furrows (table 1). The largest component of the capital cost is the expenditure for laser leveling. The siphon tubes, tarps and wooden stakes are relatively inexpensive, but more of these are required when using the shorter furrow lengths. The estimated annual capital cost, without laser leveling, is $1.43 per acre when using 1/4-mile furrows and $1.78 per acre when using 1/6-mile furrows.

The estimated annual capital cost of a gated pipe system is $46.65 per acre when using 1/4-mile furrows and $55.45 per acre when using 1/6-mile furrows (table 1). One mile of gated pipe and 1/4 mile of transportation pipe are required when using 1/4-mile furrows, while 1.5 miles of gated pipe and 1/3 mile of transportation pipe are required when using 1/6-mile furrows. The cost of laser leveling accounts for 29% of the total annual capital cost of gated pipe systems. Without laser leveling, the estimated annual capital cost of a gated pipe system would be $33.25 per acre when using 1/4-mile furrows and $42.05 per acre when using 1/6-mile furrows.

Several farmers in Broadview reduce the capital cost of gated pipe systems by using an earthen head ditch, rather than gated pipe, to irrigate the highest portion of a field. This practice reduces the amount of gated pipe required by 1/2 mile, while still providing many of the benefits of using gated pipe in other portions of the field. The estimated capital cost of a gated pipe system with an earthen head ditch is $39.39 per acre when using 1/4-mile furrows and $48.19 per acre when using 1/6-mile furrows (table 1). The initial cost of a gated pipe system that can be used to irrigate 300 acres is reduced by $7.25 per acre when one of the lines is replaced by an earthen head ditch.

The estimated purchase price of a sprinkler system that can be used to irrigate a 150-acre field is $49,341. This system includes 3/4 mile of transportation pipe and 3 miles of lateral pipe that are used to deliver water in six sprinkler lines per field. The six 1/2-mile lines must be moved 11 or 12 times to irrigate the 150-acre field. The estimated capital cost also includes a booster pump and diesel engine for lifting water from a delivery canal and adding sufficient pressure to operate the sprinklers. Most farmers use sprinkler systems to irrigate more than one field each year by scheduling irrigations sequentially and by using sprinkler systems on more than one crop. The estimated annual capital cost of a sprinkler system that can irrigate a 150-acre field is $73.45 per acre (table 1). The average cost is reduced when farmers are able to irrigate more than one field with one sprinkler system.

Labor costs

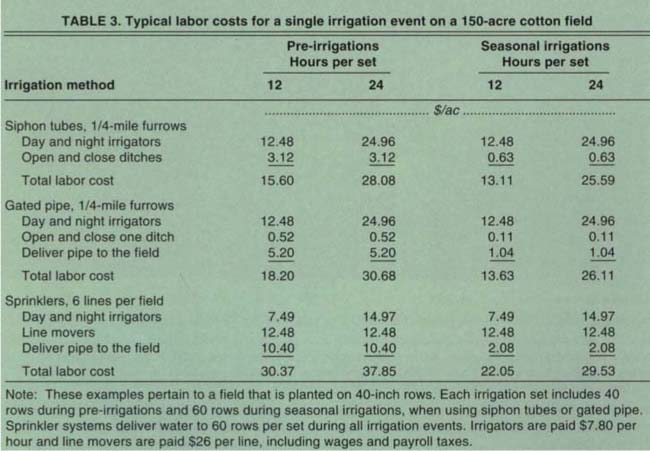

The largest component of labor costs for siphon tube and gated pipe irrigation systems is the expense for day and night irrigators to manage each irrigation event. The estimated cost of an irrigator is $7.80 per hour, or $93.60 per 12-hour shift, including wages and payroll taxes. Therefore the cost of day and night irrigators is $187.20 per 24-hour day, or $1,872 ($12.48 per acre) for a 10-day irrigation event. In the past, most farmers hired only day irrigators and did not monitor water deliveries closely during the night. In recent years many farmers have hired night irrigators, even though this doubles their expenditure for irrigation labor.

Young cotton plants irrigated with sprinklers. Sprinkler systems require significantly more labor than surface irrigation methods because the sprinkler lines must be moved at regular intervals to irrigate large fields.

The cost per day for an irrigator is the same when using siphon tubes, gated pipe or sprinklers. However, the total cost of irrigators for an irrigation event is determined by the number of days required to irrigate a 150-acre field. As shown in table 2, the number of days required for an irrigation event using siphon tubes or gated pipe is determined by the crop row spacing and the number of rows irrigated in each set. For example, 20 days may be required to pre-irrigate a cotton field that is planted in 40-inch rows, if 40 rows are irrigated in each 24-hour set. Only 10 days may be required if the field is irrigated in 12-hour sets. Some late season irrigations of cantaloupes are completed in 4 to 5 days, if 40 to 60 rows are irrigated in each 12-hour set.

Farmers using sprinkler systems can usually complete an irrigation event more quickly than farmers using siphon tubes or gated pipe. A typical sprinkler line irrigates an area 37 feet wide, which is equivalent to 11 rows of cotton planted in 40-inch rows. A six-line sprinkler system irrigates 66 rows of cotton in each set. Therefore a farmer using sprinklers and 24-hour sets can irrigate a 150-acre cotton field in 12 days. Only 6 days are required if 12-hour sets are used.

The second largest component of labor costs for siphon tube systems is the labor required to open and close earthen ditches before and after a set of irrigation events. The ditches are closed to permit cultivation of fields between irrigations. A siphon tube system with 1/4-mile furrows requires two head ditches and two tailwater ditches in each 150-acre field. The estimated cost of labor to open and close these ditches is $468. A field that is irrigated using 1/6-mile furrows requires one additional set of ditches, and the estimated cost to open and close ditches is $655.20. A field that is irrigated with gated pipe and 1/4-mile furrows may require only one tailwater ditch and no head ditches. The estimated cost to open and close the tailwater ditch is $78. A field that is irrigated with gated pipe and 1/6-mile furrows may require one or two tailwater ditches.

The labor required to transport gated pipe and sprinkler systems from storage areas to fields is a significant portion of the total labor cost. For example, the estimated cost of delivering gated pipe to a field, attaching the pipes and connecting them to the booster pump is $780 when using 1/4-mile furrows and $1,014 when using 1/6-mile furrows. These estimates include the cost of picking up the pipe at the end of the irrigation season and returning the pipe and pump to a storage area. The cost is higher when using 1/6-mile furrows because there is 47% more pipe to be delivered and returned. The estimated cost to deliver, assemble and return a sprinkler system on a 150-acre field is $1,560. Sprinkler systems include more than 4 miles of pipe that must be transported and assembled.

The line movers hired to move sprinkler systems between each irrigation set are typically compensated for each line moved, rather than for the number of hours worked. Many farmers in the San Joaquin Valley pay $26 per sprinkler line, including wages and payroll taxes. Therefore the estimated cost to move a six-line system one time is $156, and the estimated cost to irrigate a 150-acre field (12 moves) is $1,872.

Table 3 presents three examples of typical labor costs for a pre-irrigation and a single seasonal irrigation event. As noted earlier, the total cost of irrigators for an irrigation event is the same for siphon tubes and gated pipe but lower for sprinklers, because fewer days are required to irrigate a field with sprinklers. The total labor cost for gated pipe is slightly higher than the labor cost for siphon tubes because the cost of labor required to deliver and remove pipe from the field is greater than the cost of opening and closing ditches. The estimated labor cost is highest for sprinklers, due to the costs of delivering and returning the sprinkler system and moving sprinkler lines across the field.

Crop-specific irrigation costs

Cotton

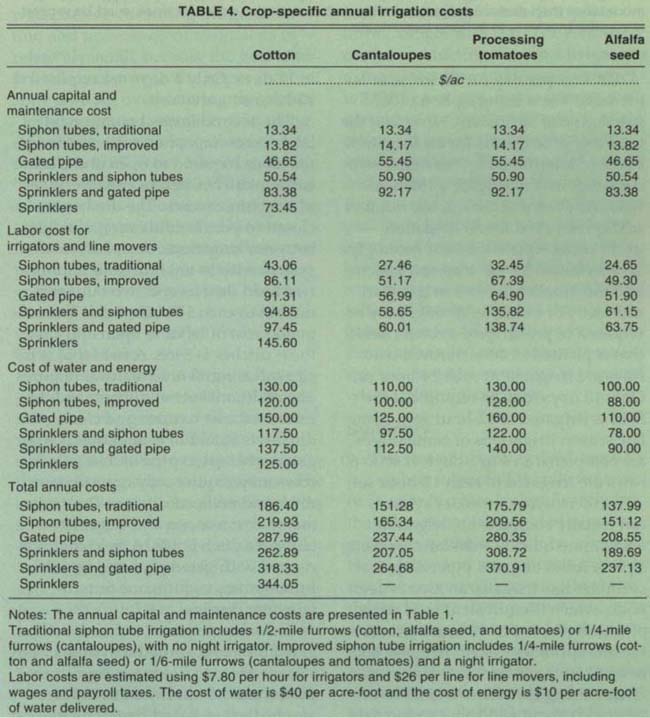

San Joaquin Valley cotton fields are usually pre-irrigated in late fall or early winter, prior to planting in March or April. Seasonal irrigations of cotton occur in June, July and August. The estimated cost of pre-irrigating and irrigating a 150-acre cotton field using siphon tubes for all irrigation events is $186.40 per acre when using 1/2-mile furrows and $219.93 per acre when using 1/4-mile furrows and hiring a night irrigator (table 4). This scenario includes five seasonal irrigations in addition to the pre-irrigation. The cost of hiring night irrigators ($43.05 per acre) is only partially offset by the $10-per-acre reduction in water cost when using the 1/4-mile furrows. Gated pipe systems generate a higher annual capital cost and they require more labor and energy than siphon tube systems, resulting in an annual irrigation cost of $287.96 per acre.

The estimated annual cost of using sprinklers for both the pre-irrigation and all seasonal irrigations of cotton is $344.05 per acre, with a labor component of $145.60 per acre. This cost can be reduced significantly by using sprinklers for the pre-irrigation only and using surface methods for all seasonal irrigations. For example, the estimated cost of using sprinklers followed by siphon tubes is $262.89 per acre, while the cost of using sprinklers followed by gated pipe is $318.33 per acre. The high cost of labor for moving sprinkler lines, and concerns about the availability of reliable line-moving crews, are often cited by farmers as principal reasons for using surface methods for seasonal irrigations.

Cantaloupes

Cantaloupe fields are also pre-irrigated in late fall or early winter to establish deep moisture in the root zone prior to planting the crop in March or April. The estimated total cost of pre-irrigating and irrigating a 150-acre field using siphon tubes is $151.28 per acre when using traditional 1/4-mile furrows and $165.34 per acre when using 1/6-mile furrows and hiring a night irrigator (table 4). This scenario includes the pre-irrigation and three seasonal irrigations. The value of water saved when using 1/6-mile furrows and a night irrigator does not justify the additional cost of irrigation labor. However, most farmers use 1/6-mile furrows for irrigating cantaloupes because yields respond positively to the improved distribution uniformity that is achieved when using shorter furrow lengths.

The estimated annual costs of using gated pipe or sprinklers to irrigate cantaloupes are significantly higher than the costs of using siphon tubes. Much of the increase is due to the amortized capital cost of the systems, but there is also an energy cost for lifting water from delivery canals and pressurizing the system. The additional cost of using sprinklers or gated pipe must be justified by improvements in distribution uniformity, reductions in drain water volume or the improved leaching of salts.

Processing tomatoes

In the San Joaquin Valley, it is common to irrigate processing tomatoes soon after planting to moisten the seed bed for germination. A pre-emergent irrigation is then delivered to minimize soil crusting that can inhibit seedling emergence and to provide moisture for the young plants. The volume of water delivered during the germination and pre-emergent irrigations is relatively small, because the goal is to provide moisture in the upper root zone without overwatering the plants.

The estimated annual cost of using siphon tubes for all irrigations on tomatoes is $175.79 per acre when using 1/2-mile furrows and $209.56 per acre when using 1/4-mile furrows and hiring a night irrigator (table 4). This scenario includes one germmation, one pre-emergent, and six seasonal irrigations. The estimated cost of conducting the same irrigations using gated pipe and 1/6-mile furrows is $280.35 per acre.

Several Broadview farmers have begun using sprinklers for the germination, pre-emergent, and first two seasonal irrigations of tomatoes, while using siphon tubes or gated pipe for the remaining seasonal irrigations. The estimated annual cost of this irrigation strategy is $308.72 per acre, while the estimated cost of using sprinklers followed by gated pipe is $370.91 per acre. The labor cost of irrigating tomatoes with sprinklers is significantly higher than for other crops in table 4 because the sprinklers are used for four irrigation events.

Alfalfa seed

Alfalfa seed is usually planted during late fall in the San Joaquin Valley and the young plants are often able to utilize rainfall in late fall, winter and spring. During the summer, farmers irrigate alfalfa seed as needed to maintain the optimal balance between vegetative growth and blossom development. If the plants receive too much water, blossom development and yield are reduced. Alfalfa seed fields are often retained for 2 or 3 years before replacement with another crop. Older fields of alfalfa seed develop deep roots that are able to extract water from a high water table. Farmers must adjust water deliveries appropriately, to avoid causing excessive vegetative growth. As a result, many farmers irrigate alfalfa seed only two or three times per year.

The estimated annual cost of irrigating alfalfa seed three times with siphon tubes is $137.99 per acre when using 1/2-mile furrows and $151.12 per acre when using 1/4-mile furrows and hiring a night irrigator. The estimated cost of conducting the same irrigations using gated pipe and 1/4-mile furrows is $208.55 per acre. Some farmers use sprinklers for the first irrigation of alfalfa seed and surface methods for later irrigations. The estimated annual cost of using sprinklers for the first irrigation and siphon tubes for later irrigations is $189.69 per acre, while the estimated cost of using sprinklers followed by gated pipe is $237.13 per acre. It is less costly to use sprinklers followed by siphon tubes than to use gated pipe for all irrigations because less water is delivered when using sprinklers, and less energy is required when using siphon tubes.

Summary

The cost of irrigating field crops using siphon tubes and 1/4-mile furrows or 1/6-mile furrows is significantly less than the cost of using gated pipe or sprinkler systems, which require additional labor and energy costs that may not be recovered by savings in water deliveries. In recent years, many farmers have begun managing surface irrigations intensively and they have achieved average water deliveries that are similar to those recorded for sprinkler systems. Sprinklers provide more uniform leaching of salts during pre-irrigations, and many farmers now use sprinklers for that task before switching to surface methods during the season. Some farmers combine gated pipe with earthen head ditches to reduce the capital cost of improved surface methods while reducing the number of ditches required in each field. These improvements in irrigation methods are partly responsible for increases in the yield of cotton and other crops that respond to improvements in irrigation distribution uniformity. They have also helped to reduce deep percolation and the volume of drain water collected in subsurface drainage systems.

Farmers will continue to implement improvements in surface irrigation methods, and they will purchase gated pipe and sprinklers when these systems can be justified economically. Public policies that provide low-interest loans or other incentives for the purchase of higher technology systems reduce the farm-level annual capital cost of these systems significantly. However, the labor and energy requirements of gated pipe and sprinkler systems will continue to limit the adoption of these irrigation methods for field crops. Many farmers have discovered that the most cost-effective strategy for reducing irrigation costs is to manage surface irrigation systems more intensively. Research that develops further improvements in surface methods will enhance farm-level efforts to improve water management and reduce subsurface drain water while maintaining economic viability.