Calag Archive

Calag Archive

Following the fuel: How portable biomass energy generation may help rural communities

Publication Information

California Agriculture 69(3):141-141. https://doi.org/10.3733/ca.v069n03p141

Published online July 01, 2015

PDF | Citation | Permissions

Full text

The forests that surround many of California's mountain communities tend to have an abundance of woody biomass and a pressing need for thinning to reduce fire danger. Revenue from selling forest residues to biomass power plants could help to support fuel reduction activities, but in many cases the nearest plant is so far away that hauling costs are prohibitive.

The remoteness of such communities can also complicate electricity provision, due to constraints on the power grid.

A Berkeley-based company has a new device that may address both problems — and it is partnering with UC researchers to test it.

Under a $2 million grant awarded in April by the California Energy Commission (CEC), All Power Labs will work with two UC research groups — the UC ANR Center for Forestry at UC Berkeley, and the Renewable and Appropriate Energy Laboratory (RAEL) in the UC Berkeley College of Natural Resources — to evaluate the feasibility of small-scale, portable biomass power.

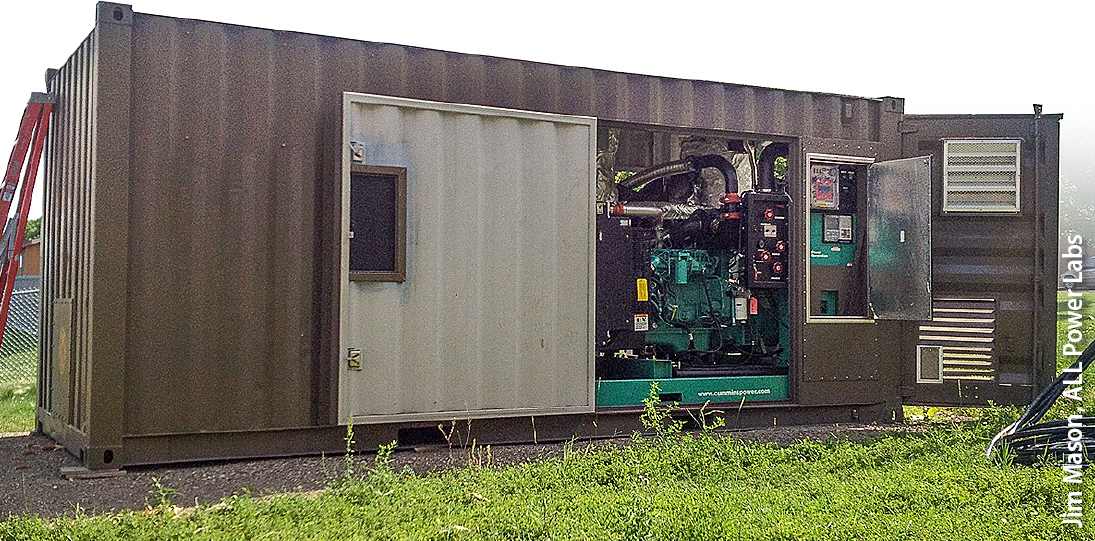

The “Powertainer” — the unit is built in a 20-foot shipping container, hence the name — uses a gasification process to generate up to 150 kilowatts from biomass such as wood chips.

The Powertainer is built into a 20-foot shipping container for portability. Fed by woody biomass, it can generate up to 150 kilowatts of electrical power.

The Powertainer's energy-conversion technology is not new, but its scale and mobility are.

“Our idea was, ‘Let's do something small that we can take to where the fuel is,’” said Tom Price, director of strategic initiatives for All Power Labs. Price said the Powertainer could be moved, connected to the grid and ready to operate in less than two days, making it easy to follow fuel sources as they become available.

“We could theoretically have a contract with (Pacific Gas and Electric Co.) to deliver energy at a number of sites and migrate like beehives migrate with crops,” he said.

Most biomass power plants in California are much bigger — by a factor of 50 or more — than the Powertainer. Other things being equal, large power plants can produce electricity at a lower cost than small ones. But a very small plant that can be moved as needed has two potential advantages that could reverse the usual economies of scale.

First, by moving close to the site of a biomass harvest, a portable plant can substantially reduce the cost of its biomass inputs. For large, stationary plants that must source feedstock from long distances, biomass trucking costs can easily account for more than half of fuel costs (see, e.g., Springsteen et al., this issue, page 142 ). In addition, because forestry operations tend to be seasonal and biomass can be stored only for a limited time before decomposition begins to create problems, it can be difficult to maintain a steady supply of fuel to a large plant throughout the year, which in turn can lead to shutdowns that increase the average cost of producing electricity.

Second, electricity generated and fed into the state's power grid in remote locations can sell for a price well above the statewide average. Because of transmission constraints, it's often difficult to keep the grid functioning properly in out-of-the-way spots — which makes additional generation capacity in those areas worth a premium. In such places, “you can provide a much larger value to the electric power system than you might by producing electricity in the Central Valley,” said Daniel Sanchez, a doctoral candidate in the Energy and Resources Group at UC Berkeley and one of the RAEL researchers on the project.

Capitalizing on these potential advantages, though, requires a better understanding of the factors involved in providing woody biomass to a small generation unit like the Powertainer, and the best places for the device to connect to the grid. The CEC grant includes $370,000 in funding to UC to develop this information.

Researchers at the Center for Forestry will evaluate several aspects of the woody biomass supply chain as it would apply to the deployment of Powertainers, including the availability of forest residues, policy issues related to thinning, and the economics of the biomass supply chain. The group will also evaluate the market potential for biochar, which is produced as a byproduct of the Powertainer's gasification process. About 10% of the carbon in the feedstock consumed by the Powertainer ends up as biochar, which can sequester carbon for hundreds or even thousands of years and may be a beneficial soil amendment.

The RAEL researchers will work to identify regions in the state with a high need for the additional power that could be delivered by a Powertainer, and assess what the economic value of that power would be. RAEL will also assess the average cost of producing electricity with the Powertainer as well as the net greenhouse gas benefits of generating electricity from forest residues with the Powertainer.

All Power Labs will be field-testing the device in Placer County as part of the grant, with staff from the county air pollution control district monitoring emissions.