Reducing water use in food processing

Home cooks know the secret to peeling tomatoes is a quick dip in hot water to loosen the skins. It takes a lot of water (and heating energy) to peel three million pounds of processing tomatoes in California each year. New UC Davis research is fine-tuning a novel way of peeling all those tomatoes with almost no water — using infrared heat.

Two methods are used to remove skins in processed tomatoes — a hot water/lye dip, or steam. The dip method uses a lot of water, a lot of energy, and creates a lot of salts . . . which presents its own disposal problem. Steam treatment heats too much of the tomato, resulting in reduced yield and quality.

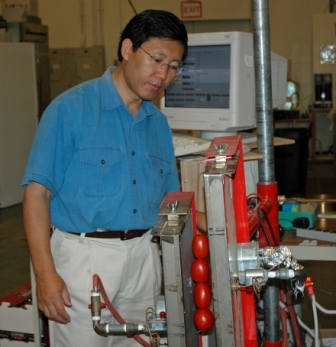

“The tomato processing industry has long been interested in finding a better way of peeling tomatoes,” says Dr. Zhongli Pan, a USDA researcher, and an adjunct professor at UC Davis. He found that peeling tomatoes with infrared heat eliminates lye use, greatly reduces water use, and results in better quality tomatoes.

Infrared heat is similar to heat from the sun and fireplaces. It allows for efficient heat transfer from the source to the product. Infrared heat has promising potential not only for dry-peeling tomatoes, peaches, and other produce, but also for blanching many fruits and vegetables before freezing, such as apples and “baby” carrots.

Pan and his colleagues are building a pilot-scale infrared tomato heating device. The goal is to develop commercial-scale guidelines for peeling tomatoes and other products with infrared heat. As California's water resources dwindle, new technologies such as this should reduce our reliance on water.

Higher-quality pizza and tomato sauces, and many other food products may appear on our tables if infrared heat can be adopted by the food-processing industry. The secondary impact on water conservation will benefit us all.

(This article was condensed from UC Davis’ “CA&ES Outlook” magazine, fall/winter 2009, page 10.)